Cee-Bee® Multi-Step Hot Section Process Overview

Cee-Bee’s alkaline rust and scale removers are specified by turbine engine OEMs and the military for cleaning hot section engine parts prior to inspection and subsequent repair processes. Turbine engines operating at extremely high temperatures cause the formation of oxide layers on hot section components. These oxide layers must be removed to allow Non-Destructive Inspection of the parent metal for cracks and fatigue. Met-L-Chek® products from McGean include a full line of approved Flourescent Penetrant Inspection (FPI) and Magnetic Particle Inspection (MPI) materials.

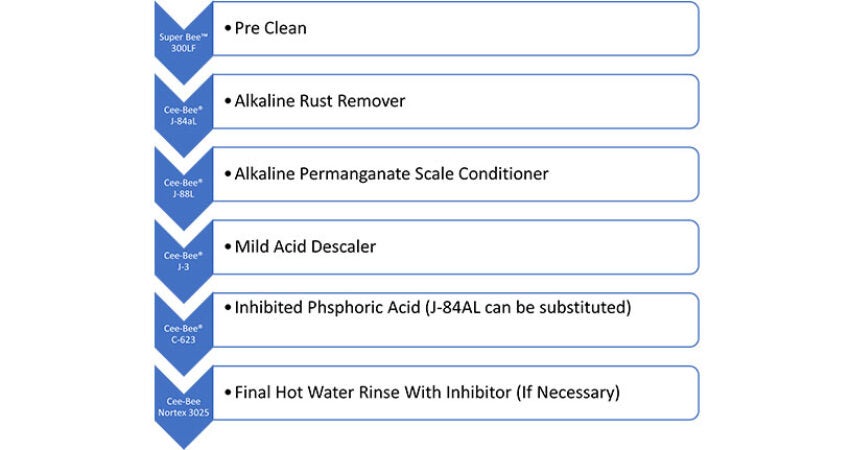

Major turbine engine OEMs (Pratt & Whitney, General Electric and Rolls-Royce) specify various multi-step engine cleaning processes, such as the one outlined below.

Step One: Aqueous Degreasing

Precleaning of parts with Super Bee™ 300LF/LFG/LFM to remove greases and oils will prevent contamination of downline descaling baths. If greases and oils are allowed into the Cee-Bee® J-84AL alkaline rust remover, these contaminants will float on top of the bath and coat parts as they are raised out of the tank.

The Super Bee™ 300LF family of products are low-foaming, all-metal-safe, concentrated liquid cleaners for use in immersion tanks, spray washers and hand cleaning operations. Operating between 120-160°F (50 – 70°C), the Super Bee™ 300LF family of products can be used at a 5 – 15% concentration for spray washer applications and 15 – 25% for immersion tank applications.

Step Two: Alkaline Rust & Scale Removers

Cee-Bee® J-84AL dissolves higher metal oxides that exist in the surface layers of high-temperature oxide scale. A sequestering agent solubilizes the oxides by forming soluble ionic metal complexes, which prevents the oxides from reattaching to the surface of the parts. Sodium hydroxide in Cee-Bee® J-84AL provides the high alkalinity environment necessary for this reaction to take place.

Cee-Bee® J-84AL

Cee-Bee’s unique analytical method for J-84AL allow both the alkalinity and sequestrant levels to be measured and controlled at the optimum level. Alkalinity is measured by titration and additions of the “whole product” are made to restore alkalinity to the correct level. The level of sequestrant, which depletes faster than alkalinity, is then measured and additions of Cee-Bee® Additive GO-2L are made to restore the sequestrant level to the correct value. Maintaining both the alkalinity and sequestering agent lead to better long-term performance of Cee-Bee® J-84AL and significantly longer bath life. Longer bath life reduces hazardous waste disposal and overall operating costs.

Step Three: Alkaline Permanganate Scale Conditioners

Cee-Bee® J-88L

Cee-Bee® J-88L is a ready-to-use, highly alkaline bath designed to oxidize (expand) difficult-to-remove scales not removed by Cee-Bee® J-84AL solutions. After processing in a Cee-Bee® J-88L bath, the conditioned, residual scale can then be removed by Cee-Bee® J-3 or Cee-Bee® C-623 (inhibited phosphoric acid).

The oxidizing agent (sodium permanganate) in Cee-Bee® J-88L is consumed more rapidly than the alkalinity (sodium hydroxide) so it is not possible to control the bath simply by making additions of the “whole product”. Alkalinity is controlled by additions of Cee-Bee® J-88L and the oxidizer is controlled by additions of Cee-Bee® J-88 Additive PL. This method allows the bath to operate at an optimum level for longer periods of time.

Step Four: Acid Descalers

Cee-Bee® J-3

Cee-Bee® J-3 is a mildly acidic liquid descaler that dissolves deeper metal oxides which are in a lower state of oxidation and not readily affected by J-84AL. Cee-Bee® J-3 is a highly effective scale remover that also has strong chelating properties. Cee-Bee® J-3 works in conjunction with Cee-Bee® J-88L, which conditions oxides for removal with its strong oxidizing action.

Step Five: Inhibited Phosphoric Acid

Cee-Bee® C-623

Cee-Bee® C-623 effectively removes scale conditioned by Cee-Bee® J-88L, along with the resulting purple stains that are a by-product of the permanganate oxidation process.

Cee-Bee® C-623 has some advantages over the alkaline rust remover as a final cleaning step. It is highly effective at removing permanganate staining, but also produces a “brighter” part, especially on nickel-based alloys. This is preferable for Fluorescent Penetrant Inspection (FPI). Parts cleaned with Cee-Bee® C-623 are easier to rinse and the bath operates at ambient temperature which reduces energy costs.

The concentration of Cee-Bee® C-623 is controlled by titration and making additions of the whole product.

Step Six: Rinsing & Corrosion Prevention

Intermediate Rinsing

For intermediate rinsing after each chemical process bath, follow these steps:

- Pressure spray rinse the part with clean water over the chemical bath to reduce chemical drag out. Drain and flush with clean water any internal passageways or cavities that may retain chemical solution.

- Fully immerse the part in clean, ambient temperature water, remove it from the water and pressure spray rinse the part.

Final Rinse

For the final rinse, complete steps 1 and 2 above, then complete step three:

- Fully immerse the parts in hot water at 150-200°F (66-93°C) until the temperature of the part is approximately the same as the water temperature to promote flash drying. To prevent flash rusting of ferrous alloys, Cee-Bee® Nortex 3025 can be added to the final rinse water bath heated to 150-170°F (66-76°C)

*Note: There are special rinsing requirements for parts going to downline thermal repairs that may require a final deionized (DI) water rinse. Please consult the OEM’s Standard Practice Manuals for limits on chloride levels in final rinse waters.

Cee-Bee® Nortex 3025

When used as directed, Cee-Bee® Nortex 3025 will not interfere with fluorescent penetrant inspection (FPI). Nortex 3025 is a water-soluble oil that leaves an ultra-thin, protective oil barrier on the surface of the part. This product gives short-term protection to ferrous alloys. For longer term protection, Cee-Bee® WDO can be applied.

Non-Destructive Inspection (NDI)

After the cleaning process is completed, many turbine engine parts are inspected for metal fatigue or cracking using Fluorescent Penetrant Inspection (FPI) or Magnetic Particle Inspection. McGean offers the full line of approved FPI and MPI inspection materials qualified to AMS 2644.

Please contact your local Cee-Bee® representative if you have any further questions or would like more information on this process or its alternatives.